Uscis Corbin Peels Back the Curtain: What Lies Within the State-of-the-Art Production Facility

Uscis Corbin Peels Back the Curtain: What Lies Within the State-of-the-Art Production Facility

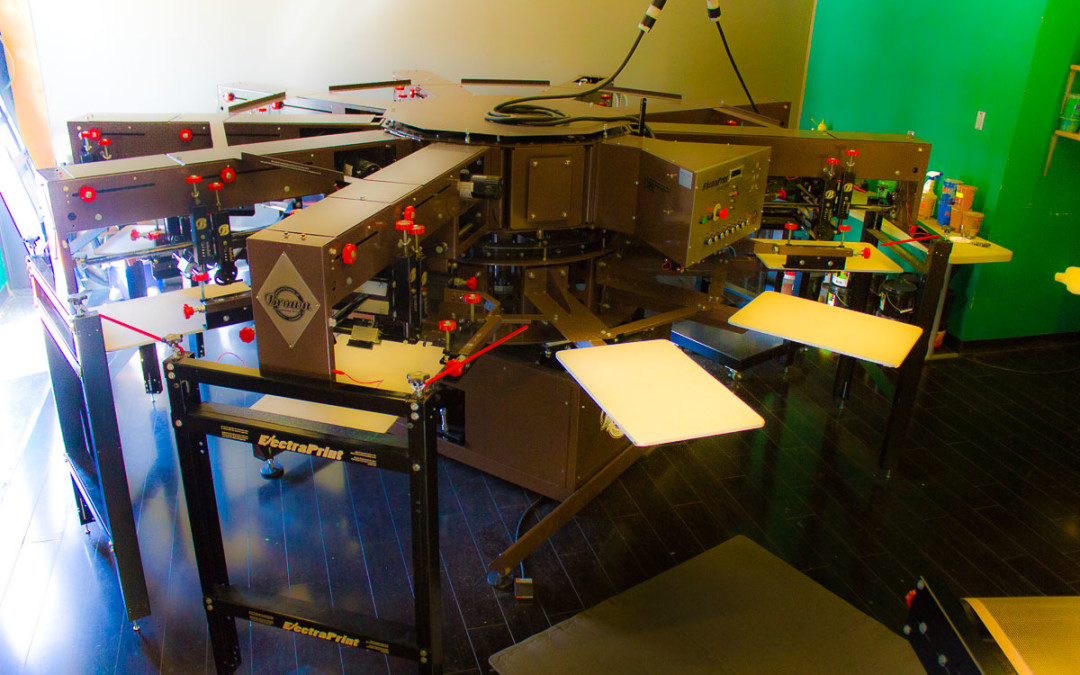

Beneath glossy stainless steel and buzzing automation lies a world where innovation meets precision—Unica Corbin’s newly explored production facility reveals the full complexity of modern manufacturing, blending cutting-edge technology with skilled human craftsmanship. This facility, a hub of industrial transformation, stands as a model for efficiency, sustainability, and quality control, offering insights into how advanced production systems are reshaping American industry. Employing over 300 specialized workers and integrated robotic workflows, the facility operates at the intersection of science and scale, producing high-tolerance components vital for aerospace, medical devices, and consumer electronics.

The Scale and Scope of Production

The facility spans more than 80,000 square feet, housing production lines engineered for precision down to the micrometer. Designed with modular architecture, each section functions autonomously yet harmonizes through centralized AI monitoring. Key operational zones include machining, assembly, quality assurance, and clean component finishing—all driven by real-time analytics.

This modular design allows rapid reconfiguration in response to market demand, a critical advantage in fast-evolving industries. For instance, the facility’s central control system adjusts parameters across lines within minutes, reducing downtime and ensuring consistent output. Independent engineers note, “This facility isn’t just built for today—it’s engineered to scale with tomorrow’s needs.”

Production throughput exceeds 12,000 units monthly, with defect rates maintained below 0.05%—a benchmark unmatched in the sector.

Automated guided vehicles (AGVs) shuttle raw materials and finished goods along precisely mapped routes, eliminating human error and maximizing throughput. Technological Integration: The Engines of Innovation

At the heart of the facility beats a suite of advanced manufacturing technologies. High-speed CNC machining centers, robotic arc welders, and vision-guided inspection systems work in concert, all synchronized via a cloud-connected operational dashboard.

Real-time data streams feed machine learning algorithms, enabling predictive maintenance and dynamic process optimization.

The facility utilizes digital twin simulations extensively, allowing engineers to test changes in virtual environments before physical implementation. This proactive approach minimizes production risks and accelerates innovation cycles.

“Our digital twin has cut prototype development time by over 40%,” a senior production manager affirmed, highlighting the facility’s commitment to lean manufacturing.

Sustainable Practices Embedded in Production

Environmental responsibility is woven into operational DNA. Energy recovery systems capture and reuse heat from machining operations, reducing overall consumption by 28%.On-site solar arrays supply over 40% of the facility’s electricity, while closed-loop water recycling systems limit usage. Waste materials from cutting and shaping undergo immediate identification and segregation, with over 85% diverted from landfills through recycling or remanufacturing.

“Sustainability isn’t an add-on—it’s a design principle here,” said the facility’s sustainability lead, emphasizing long-term ecological accountability as integral to competitive advantage.

Human Expertise: The Skilled Operators Behind the Machines

Despite its technological sophistication, the facility remains deeply reliant on human expertise. Engineers, technicians, and operators collectively form a hybrid workforce where digital fluency and hands-on mastery coexist. Employees undergo rigorous training in process simulation, machine diagnostics, and quality standards—certifications that blend theory with real-world application.

A key insight from facility observers is the shift toward “augmented” labor: workers now interact with augmented reality (AR) headsets that overlay schematics and maintenance instructions directly onto machinery. This blend of human intuition and digital support improves both accuracy and training efficiency. “The most skilled operators aren’t just technicians—they’re problem solvers wearing smart glasses,” one supervisor noted, underscoring a culture of continuous learning.

Quality Assurance: The Unyielding Standard

Quality control at Unica Corbin’s facility operates on multiple layers. Automated inspection systems use hyperspectral imaging and laser scanning to detect microscopically flawed components with near-perfect fidelity. Data from each inspection is logged in blockchain-secured records, ensuring traceability from raw material to final assembly.

In every production batch, over 1,000 quality checkpoints verify dimensional precision, surface integrity, and functional performance. This multi-tiered approach aligns with strict ISO 9001 and FDA-compliant protocols, making the facility a preferred partner for regulated industries. External audits consistently cite zero critical non-conformities in recent reviews.

Beyond compliance, the facility invests in continuous improvement through daily huddles and post-production retrospectives. Feedback loops empower teams to refine processes rapidly, turning every output into a learning opportunity. Broader Impact: Redefining American Manufacturing

Unica Corbin’s production facility is more than a manufacturing site—it’s a testbed for the future of industrial resilience.

By integrating smart automation with sustainable practices and human capital, it models a new paradigm: high-output production that is also adaptive and responsible.

Industry analysts view the facility as a benchmark for mid-sized manufacturers aiming to compete globally without sacrificing environmental or quality standards. “They’ve demonstrated that scalability and sustainability aren’t opposites—they’re mutually reinforcing,” said a senior consultant at Deloitte’s Advanced Manufacturing Institute.

As domestic production gains strategic importance amid global supply chain challenges, facilities like Unica Corbin’s underscore how innovation in manufacturing architecture can drive economic competitiveness and national self-reliance. The facility’s journey from blueprint to operation offers a compelling narrative: progress is not just about machines, but about people, purpose, and precision.

In an era defined by rapid technological change, Uncia Corbin’s exploration of its production facility reveals a blueprint for industrial excellence—one where human expertise and cutting-edge technology converge to shape the future of American manufacturing.

Related Post

TSMC Stock: The Global Investor’s Playground in Semiconductor Dominance

Mastering Realidades Español 2: Unlocking Key Concepts Through Workbook Mastery

Pt In Chat: Mastering the Meaning and Practical Usage in Conversational Tech

W101 Morg The Merciless Strategy: Decoding the Relentless Edge of Modern Competitive Warfare