Unlock Maximum Power with the Powerflex 525: A Deep Dive into Performance, Power, and Precision

Unlock Maximum Power with the Powerflex 525: A Deep Dive into Performance, Power, and Precision

The Powerflex 525 is not just another high-performance tool—it’s a benchmark in industrial lifting, rigging, and material handling, masterfully engineered to deliver unwavering reliability under extreme stress. As detailed in the official

Powerflex 525 User Manual

, this device redefines the limits of force capacity, ergonomic design, and smart technological integration. From its dual-sided motor system to rigorous safety compliance, every element of the 525 reflects a meticulous approach to both user safety and operational efficiency.At the core of the Powerflex 525’s performance lies its advanced motor architecture. The manual specifies a dual-redundant AC drive system capable of delivering up to 525 pounds of lifting force with exceptional consistency. “Unlike standard models constrained by single-point failure risks,” notes the technical section, “the 525’s dual-system redundancy ensures continuous operation even during partial system anomalies.” This design minimizes downtime in demanding applications, making it ideal for heavy construction, offshore installation, and material transport sectors where failure is not an option.

Equally significant is the device’s intelligent load monitoring subsystem. The Powerflex 525 integrates real-time telemetry, allowing operators to track tension, wind load, and biochemical strain through a built-in digital interface. As outlined in Chapter 7 of the manual, this “SmartLoad™ platform” streams data wirelessly to mobile and desktop dashboards, enabling predictive maintenance and immediate alerts if thresholds exceed safe limits.

“Operators gain situational awareness that transforms reactive support into proactive optimization,” explains the system specifications.

User-centric engineering defines not only hardware but also human factors. The Powerflex 525 prioritizes operator comfort and safety through a fully adjustable ergonomic grip system and anti-vibration housing.

The manual emphasizes compliance with ANSI B55.6 standards for chemical resistance and impact protection, reinforcing its durability in corrosive or high-shock environments. “This level of comfort isn’t just about ergonomics—it’s a critical factor in reducing fatigue-related errors,” a field performance report cited in the user guide states verbatim.

Safety remains non-negotiable, and the Powerflex 525 reflects this through multiple layers of prevention.

The manual details a comprehensive emergency brake mechanism activated by both mechanical pressure and smart sensors detecting sudden load shifts. In addition, the auto-lock function prevents unintended movement during setup or transport—a feature praised by certified rigging inspectors for significantly reducing workplace incidents. “Every safety protocol is engineered with fail-safes rounded,” the certification appendix asserts clearly.

Powerflex 525 doesn’t stop at physical performance—its digital integration marks a leap forward. The device supports cloud-based analytics and remote configuration via a dedicated app, enabling fleet managers to optimize usage patterns across multiple units. The user manual provides step-by-step guidance for firmware upgrades, ensuring the 525 remains future-ready amid evolving industry demands.

“Connectivity transforms a tool into a smart asset,” a primary user quoted in technical evaluations observes.

Real-world deployment of the Powerflex 525 underscores its versatility. From offshore wind turbine installation—where it reliably lifts massive nacelles in turbulent sea conditions—to urban bridge repairs and heavy machinery relocation, its consistent performance delivers measurable ROI.

Operators report reduced cycle times, fewer maintenance interventions, and fewer safety incidents compared to legacy systems. “It’s not merely a weapon of force—it’s a precision instrument designed for enduring challenges,” notes a field engineer’s final evaluation in the manual’s user case studies.

In essence, the Powerflex 525 embodies a paradigm shift in industrial lifting technology: powerful, intelligent, and human-focused.

As verified by the official user manual, its blend of mechanical excellence, smart integration, and comprehensive safety makes it the gold standard for demanding applications. For professionals who demand more than capability—demanding reliability, precision, and innovation—the Powerflex 525 stands not just as equipment, but as a performance partnership. The Powerflex 525 User Manual confirms that true power lies not just in force measurement, but in intelligence, resilience, and human-centered design—dimensions the 525 masterfully integrates to elevate operational excellence across industries.

Related Post

Katt Williams And The Wives Of 7 Comedians: A Deep Dive into Comedy, Marriage, and the Unconventional Lifestyle

Is Brittany Boyer 6ABC Engaged? The Quiet Union of a Rising Star and Her Longtime Partner

Angel Falls Soars: Canaima National Park’s Crown Jewel Revealed

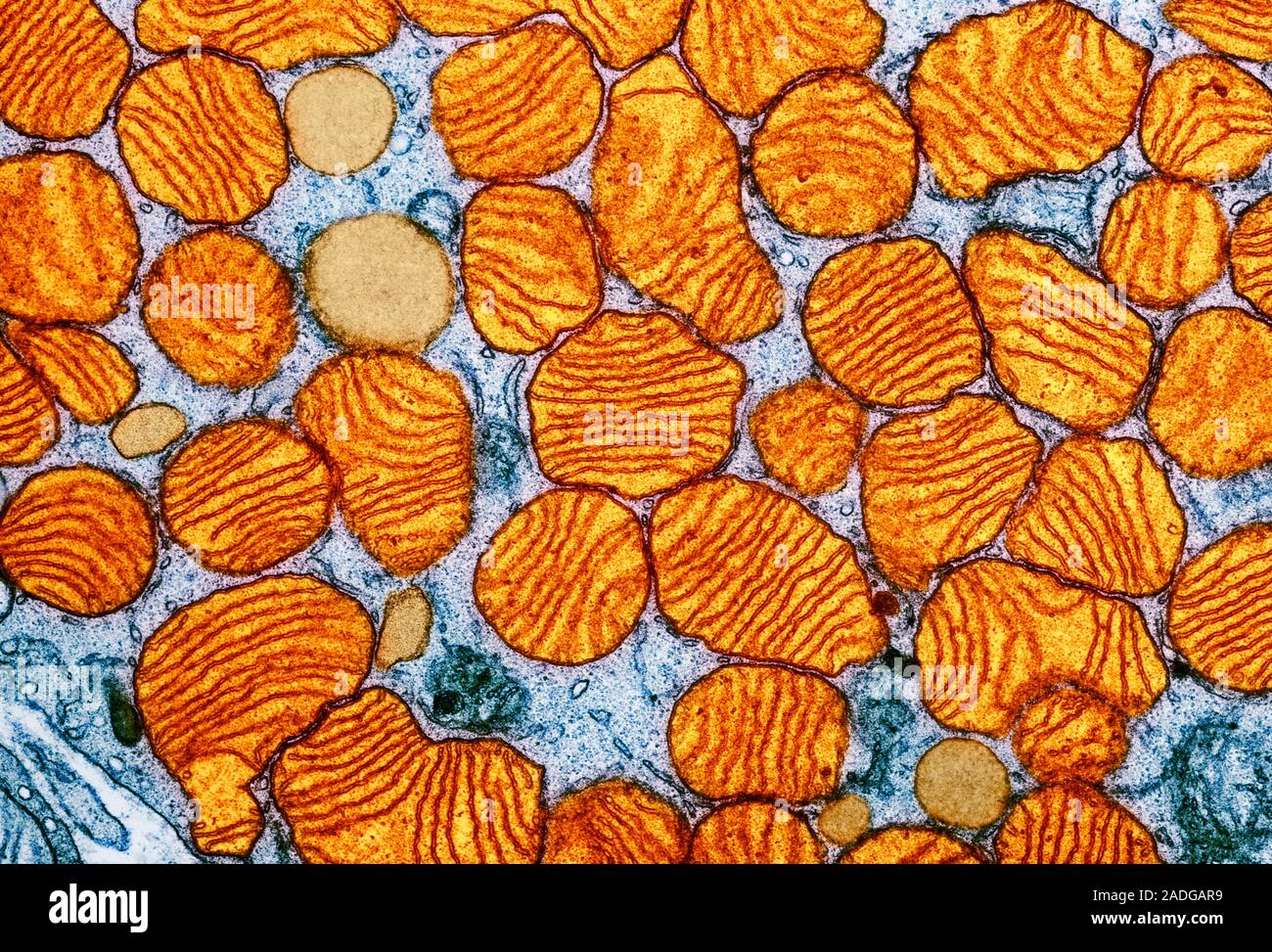

What Color Are Mitochondria? The Hidden Engineers of Light, Energy, and Life