Operador de Máquina CNC: O Que Faz—A Tecnologia Por Trás da Precisão Industrial

Operador de Máquina CNC: O Que Faz—A Tecnologia Por Trás da Precisão Industrial

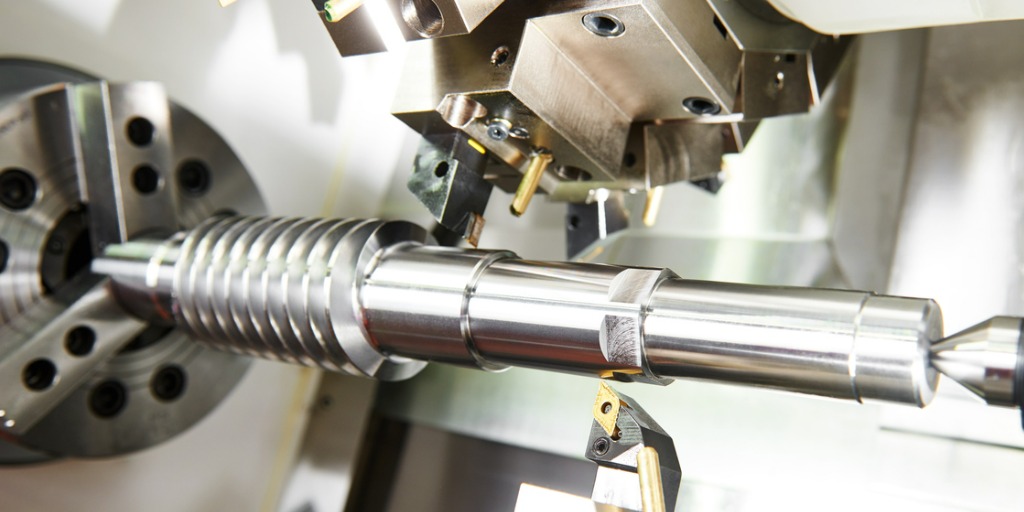

Operadora de Máquina CNC, or CNC machine operator, stands at the intersection of tradition and cutting-edge automation. These specialized professionals serve as the vital human interface with highly sophisticated automated systems, guiding CNC (Computer Numerical Control) machines to transform raw materials into precise, high-quality components across industries such as aerospace, automotive, and medical device manufacturing. Far more than mere switches or controllers, CNC operators are the brain behind the precision, ensuring that programmed instructions accurately guide machines in executing complex, repetitive tasks with micron-level accuracy.

As advanced manufacturing evolves, understanding the precise role and responsibilities of the CNC operator becomes essential for appreciating modern industrial capability. At its core, a CNC machine translates digital blueprints—CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) files—into physical parts by directing motorized tools along programmed paths. While automation handles the mechanical repetition, the operator remains irreplaceable in monitoring, adjusting, and validating every stage of production.

According to industry experts, “CNC operators are the guardians of quality—without their vigilance, even the most advanced machine risks producing defective output.” Their expertise ensures tight tolerances, material integrity, and process consistency critical to high-stakes applications.

The Operator’s Key Responsibilities: From Setup to Supervision

Operating a CNC machine involves a multifaceted workflow that begins well before the machine starts cutting. The operator’s role spans several critical stages: - **Program Verification:** Before production, operators review and validate the G-code—the machine’s native language—ensuring commands match design specifications.Any error, no matter how minor, can lead to costly defects. - **Machine Preparation:** This includes selecting appropriate tools, loading workpieces, setting proper speeds and feeds, and configuring fixtures. Safety protocols are enforced at every step to prevent accidents.

- **Monitoring Process Execution:** During machining, operators track tool wear, monitor machine performance, and interpret sensor feedback. Sudden deviations prompt immediate corrective actions to maintain quality. - **Post-Operation Logistics:** After machining, operators assist in unloading parts, cleaning tools, updating logs, and preparing machines for subsequent jobs.

This ensures operational efficiency and tracesability. “Every CNC cycle depends on the operator’s keen eye and technical judgment,” notes a senior machinist. “It’s not enough to press start—the operator must actively safeguard each phase.”

Technical Expertise: The Skill Set of a Modern CNC Operator

Beyond mechanical know-how, today’s CNC operators must command a diverse technical aptitude.Mastery typically includes: - **Proficiency in CNC Software:** Understanding CAM-generated toolpaths, G-code syntax, and post-processor settings rounds out essential competencies. Operators often interface with software to fine-tune jobs, troubleshoot discrepancies, and optimize machining times. - **Machine-Specific Knowledge:** Each CNC machine—whether mill, lathe, or multi-axis router—has unique behaviors.

Operators develop muscle memory through hands-on experience across multiple machine types. - **Metrology and Quality Control:** Using calipers, micrometers, and coordinate measuring machines (CMM), operators verify dimensional accuracy, ensuring parts meet strict industry standards such as ISO or ASME. - **Problem-Solving Under Pressure:** When unexpected issues arise—tool breakage, material inconsistency, or CNC errors—operators must diagnose and resolve problems swiftly.

“Responding accurately under tight schedules defines an effective operator,” explains an industry consultant. This blend of technical skills forms a profile distinct from older machine tenders, reflecting the shift toward digital manufacturing ecosystems where human judgment complements machine precision.

Industrial Impact: Why CNC Operators Remain Indispensable

The rise of automation has sparked concern about workforce obsolescence, yet CNC operators exemplify how human expertise evolves alongside technology.Far from redundant, their role has transformed into one of interpretive oversight—merging technical experience with real-time decision-making. “Operators are not just executing programs—they’re actively enhancing productivity and reducing waste,” states a leader in precision manufacturing. They ensure processes remain adaptive rather than rigid, fine-tuning operations where automation alone cannot respond to variable demands.

Furthermore, CNC operators drive operational continuity in environments where margin for error is virtually nonexistent. In aerospace, where a single micrometer can compromise safety, or in automotive manufacturing, where engine components demand micron-level precision, their presence prevents costly failures and ensures compliance. Their role reinforces a symbiotic relationship between human intuition and computer execution, a cornerstone of Industry 4.0 advancement.

Future Trends: Evolving Roles in a Digitized Workshop

As artificial intelligence, IoT, and predictive maintenance reshape factory floors, CNC operators are increasingly expected to integrate smart systems into workflows. Real-time data analytics now enable proactive maintenance alerts, while CNC software upgrades support adaptive machining. Operators must remain agile learners, embracing new tools and collaborative robotics (cobots) that assist in repetitive tasks, freeing human focus on strategic oversight.This evolution emphasizes continuous training and upskilling—not mitigation of job displacement. As industry pioneers recognize, the operator’s future lies not in resisting change but in mastering it, transforming CNC expertise into a dynamic, evolving career path.

The Human Element in Precision Engineering

Beyond polished machining reports and statistical process control, the CNC operator embodies the human element in high-tech manufacturing.Their vigilance, technical acumen, and adaptive problem-solving ensure that automation delivers not just speed, but reliability and excellence. In the quiet hum of a CNC workshop, it is the operator’s touch—both literal and intellectual—beyond machines that turns digital code into functional reality, sustaining the backbone of modern industrial production.

Related Post

Operador de Máquina CNC: O Que Faz? The Core of Modern Manufacturing Precision

Operador De Máquina CNC: O Que Faz e Como Transforma Indústria

Operador de Máquina CNC: O Que Faz e Por Que É Indispensável na Manufatura Moderna

Spice Up Your Ears: The Hottest Spicy Audiobooks Stealing Spotify’s Audience