Oil Rig Chem: The Lifeblood Behind Deepwater Extraction and Rig Safety

Oil Rig Chem: The Lifeblood Behind Deepwater Extraction and Rig Safety

Beneath the crashing waves and shifting ocean floors lies a complex chemical ecosystem that powers offshore oil operations. Oil Rig Chemistry is not just a behind-the-scenes discipline—it is the essential science that ensures operational efficiency, environmental protection, and structural integrity in some of the most extreme environments on Earth. From preventing corrosion and maintaining wellbore stability to managing reservoir fluids and mitigating fire risks, chemical treatment systems are integral to modern offshore drilling.

As rigs push deeper and extract oil under increasingly harsh conditions, the precision and reliability of these chemical processes have never been more critical.

The Chemical Arsenal: How Oil Rig Chemistry Powers Extraction

At the core of oil rig operations, chemistry acts as both protector and facilitator. The primary challenges—extreme pressure, corrosive brines, high temperatures, and volatile hydrocarbons—demand tailored chemical solutions to keep machinery functional and production flowing.- **Scale and Corrosion Inhibitors**: Oil and water mixed in subsea environments generate mineral scales and corrosive hydrogen sulfide (H₂S), which can severely degrade infrastructure. Chemical additives like fatty amines, phosphonates, and polyphosphates are injected continuously to inhibit scale formation and neutralize corrosive agents. As Dr.

Elena Torres, a senior chemical engineer at offshore operators, notes: “Without targeted inhibitors, pipelines and wellbores would degrade within weeks—inviting leaks and production downtime.” - **Drilling Fluid Chemistry**: Hydraulic fracturing and drilling require specialized mud systems engineered with polymers, clays, and surfactants. These formulations control viscosity, stabilize formations, carry drill cuttings, and prevent well collapse. Polymeric additives such as xanthan gum enhance fluid retention, reducing risks of lost circulation into fractured rock.

- **Reservoir Management Chemicals**: By treating formation fluids with thermal or chemical additives, operators adjust wettability, reduce interfacial tension, and improve hydrocarbon flow. Surfactants and biocides are frequently used to optimize production while preventing microbial-induced corrosion and biofilm buildup. - **Fire and Gas Mitigation**: Offshore platforms face constant threats from flammable gas leaks and hydrocarbon vapor accumulation.

Chemical suppression systems, including dry chemical agents (like monoammonium phosphate) and foam systems, extinguish fires faster than mechanical systems in confined rig spaces—critical for safety and compliance.

Operational Reliability Through Chemical Monitoring and Automation

Beyond direct treatment, real-time chemical monitoring ensures that rig systems remain within safe operational parameters. Sensors deployed in production lines, ballast tanks, and blowout preventers continuously analyze chemical composition, pH, oxygen levels, and hydrogen sulfide concentrations.Data from these systems feed automated controls that adjust dosing rates or trigger alarms when anomalies are detected. - The integration of digital chemistry platforms enables predictive maintenance, reducing costly unplanned outages. “Chemical analytics are no longer reactive—they’re proactive,” explains Mark Chen, a rig operations chemist.

“We use AI-driven models to forecast chemical depletion and adjust treatment schedules before a failure occurs.” - Sampling and lab analysis remain vital for verifying chemical performance. Frequent testing of produced fluids for salinity, acidity, and inhibitor concentration ensures consistency across dynamic offshore conditions. This dual approach—continuous sensing paired with lab validation—forms the backbone of chemical integrity programs on modern rigs.

Environmental Stewardship and Regulatory Compliance

Oil Rig Chemistry also serves a critical sustainability role. Paraffin and hydrate inhibitors keep flow restrictions minimal, reducing the need for energy-intensive heating or mechanical intervention—thus lowering emissions. Moreover, chemistry-based treatment prevents accidental releases of toxic substances, supporting compliance with stringent international regulations like MARPOL and OSHA standards.- Disposal of spent chemicals now emphasizes eco-friendly recovery and neutralization. Rig waste streams are treated with alkaline or chemical oxidation processes to safely neutralize acids and hydrocarbons before environmental release. Advanced filtration and packed-bed reactors have improved efficiency in minimizing chemical discharge.

Challenges and Innovations in Harsh Offshore Environments

Operating in deepwater and Arctic conditions intensifies chemical handling complexity. Extreme cold, high salinity, and unpredictable weather strain conventional formulations and delivery systems. Engineers are innovating with cold-resistant polymers, nano-enabled corrosion coatings, and specialized encapsulated inhibitors designed to release active ingredients only under precise conditions.- A breakthrough in recent years involves smart release chemistries—microcapsules that dissolve only when triggered by temperature, pressure, or pH changes. These adaptive systems improve chemical efficiency and reduce quantity overuse, enhancing both economic and environmental performance. - Training remains key: rig personnel must deeply understand chemical properties, dosing protocols, and emergency response.

Rigorous certification programs ensure that crew expertise matches technological advances.

Oil Rig Chemistry functions as the silent guardian of offshore production—an invisible layer of science that enables safe, efficient, and environmentally responsible extraction from the ocean floor. As technology evolves, the field continues to redefine what’s possible in extreme marine environments, turning chemical innovation into operational resilience and long-term sustainability.

Related Post

Discovering Movies4U Hindi: Your Ultimate Guide to Streaming Bollywood Films

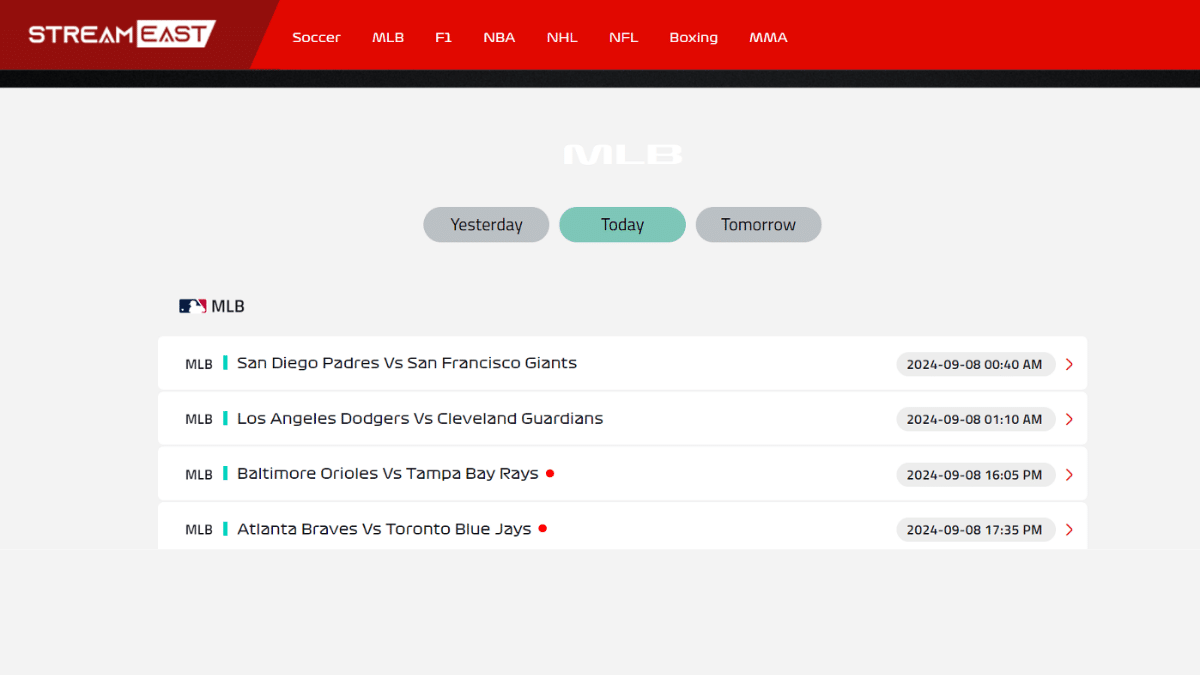

Stream East Is Revolutionizing Live Video with Unprecedented Speed and Accessibility

You Are The Queen Of My Heart: Unraveling the Hindi Translation & Profound Symbolism

How the Houston Texans Shape the Future with a Strategic Depth Chart