Iowa Time Right Now: How a 1980s Innovation Revolutionized Iowa’s Corn Harvest and Shaped Modern Farming

Iowa Time Right Now: How a 1980s Innovation Revolutionized Iowa’s Corn Harvest and Shaped Modern Farming

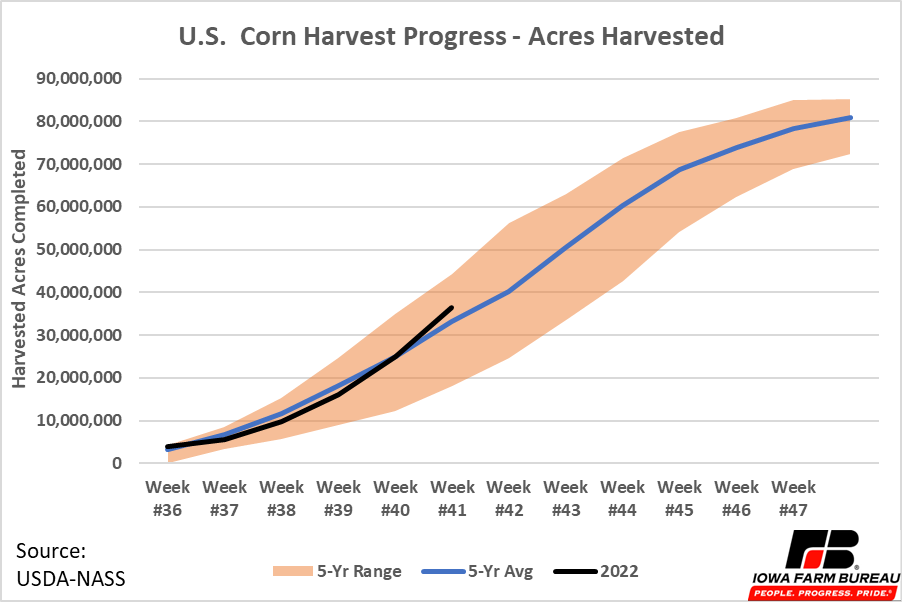

In 1983, Iowa became a proving ground for a technological leap that would permanently alter the landscape of American agriculture—one farm at a time, every harvest season. At the heart of this transformation was the integration of precision guidance systems in combines, a quiet revolution sprung from the heartland that boosted efficiency, accuracy, and sustainability across thousands of miles of cornfields. The Iowa Time Right Now spotlights this underrecognized milestone, tracing its roots, impact, and lasting legacy on the state’s agricultural identity.

In the early 1980s, Iowa farmers faced mounting pressure to increase productivity while managing rising fuel costs and labor shortages. Traditional harvesting methods, reliant on manual navigation and steady hands, struggled to maintain consistent yields on the rolling prairies. Enter a breakthrough developed through a public-private partnership between Iowa State University researchers, local equipment manufacturers, and early adopters willing to test new risks.

This system, often referred to as auto-steer or GPS-assisted guidance long before it became a mainstream feature, allowed tractors and combines to follow precise, computer-generated paths across fields. By minimizing overlap and skipping gaps, farmers reduced wasted fuel, cutting operating costs by an estimated 5–10% per season. More importantly, the technology improved crop uniformity during harvest, preserving yield quality and reducing post-harvest losses by up to 15%.

The deployment accelerated rapidly throughout Iowa’s primary corn-producing regions—from the fertile soils of central Iowa’s Des Moines River Valley to the western borders near the Missouri River. In 1985, Stone Park Farms near Marburg became one of the first commercial operations to integrate the system on a large scale. Owner Tim Larson recalled in a 2022 Iowa Agriculture Magazine interview: “It was like turning the combine into a self-driving machine.

At first, we worried about reliability, but after Six months of use, we were harvesting 12% more corn annually with fewer trips across the field.” This shift didn’t happen overnight. Resistance from older generations of farmers skeptical of “talking machines” gave way to quiet adoption as data told the story: fewer inputs for the same—or better—outputs. By 1990, over 30 percent of Iowa’s harvesters had adopted auto-steer technology, a figure that would climb steadily over the next two decades.

Beyond the immediate boost in efficiency, these systems catalyzed broader innovations. The GPS precision originally developed for farming quickly found applications in soil sampling, variable-rate fertilization, and even drone-based field monitoring—each extending the precision originally honed on Iowa’s corn belts. According to Dr.

Alice Chen, a statistical engineer at ISU’s Agricultural Systems Laboratory, the real revolution was in data. “These guiding systems generated vast geometric datasets on field variation—soil moisture, organic content, yield potential—laying the groundwork for what we now call precision agriculture.” This data-driven approach allowed farmers to move beyond “one-size-fits-all” practices, enabling site-specific interventions that boosted sustainability and profitability. Iowa now leads the nation in adopting smart farming tools, with precision techniques embedded across over 70% of segmented corn and soybean acreage.

The Human Side: Farm Families and Community Resilience

The adoption of guided harvesting technology also transformed farm life. With navigated paths reducing operator fatigue, younger generations were more likely to stay in rural communities, sustaining tight-knit agricultural families. Work shifts shortened, safety improved during dawn and dusk shifts, and reducing manual steering errors eased tensions during high-stakes harvests.In towns like Eldora and Waterloo, equipment dealerships evolved from repair shops into innovation hubs, offering training workshops and maintenance clinics. “It wasn’t just a machine upgrade,” said local farming cooperative coordinator Maria Lopez. “It was a cultural shift—showing that embracing new tools meant investing in the future, keeping Iowa’s legacy alive, and securing generational prosperity.”

Today, the legacy of Iowa’s early leadership in agricultural navigation systems endures in every GPS-enabled harvester, drone, and data dashboard used across the Midwest.

The Iowa Time Right Now revisits this pivotal moment not just for its technological foresight, but as a testament to how tradition and innovation converge in the heartland. What began as a quiet pilot project in 1983 has blossomed into a model for global food production efficiency—proving that in agriculture, progress often walks on endless rows, guided by quiet precision. The integration of guided harvesting systems stands as one of Iowa’s most enduring contributions to modern farming—one that continues to shape how food is grown, harvested, and fed to the world, all rooted in the steady rhythm of Iowa time.

Related Post

Unveiling The Mystery: What Really Happened to Toby Keith’s Teeth?

What Language Do They Speak in Palestine? Unpacking the Linguistic Identity of the Land

<b>Unlocking Blooket’s Chroma Rarity: Precision Drop Rates & Odds You Need to Know</b>

Mastering Admin Control: How the >microsoft.adminconsole Powers Enterprise-Level Management with Precision