Intertherm Furnace: The Industrial Workhorse Redefining Precision and Efficiency in High-Temperature Processing

Intertherm Furnace: The Industrial Workhorse Redefining Precision and Efficiency in High-Temperature Processing

In an era where performance, reliability, and energy efficiency define industrial success, the Intertherm furnace stands out as a crown jewel in high-temperature processing. Engineered for demanding applications across metallurgy, glass manufacturing, ceramics, and waste treatment, this furnace delivers consistent thermal control with minimal downtime. Its innovative design merges advanced materials, smart temperature regulation, and robust construction to meet the exacting standards of modern industry.

As manufacturers push the boundaries of temperature control and energy optimization, the Intertherm furnace has emerged not just as a machine—but as a critical enabler of sustainable, high-output production.

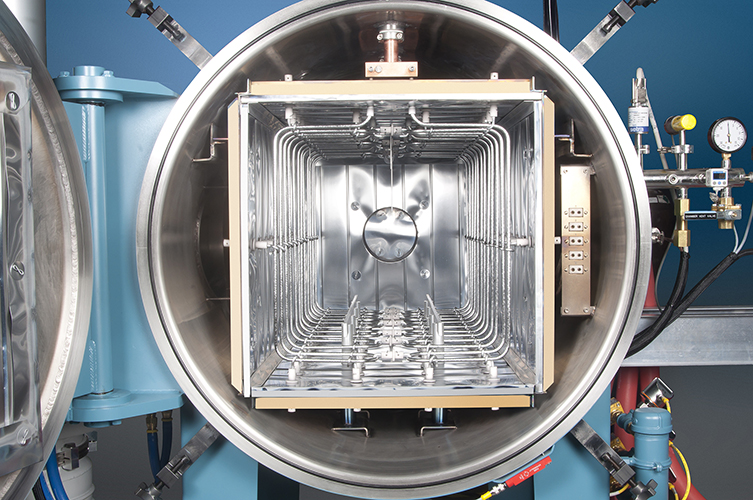

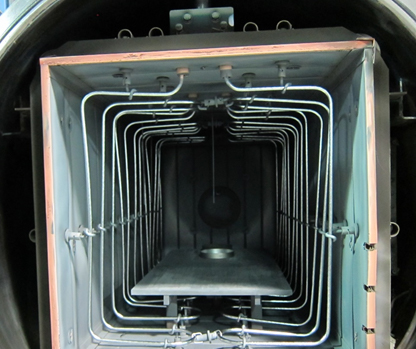

At its core, the Intertherm furnace is a marvel of industrial engineering, built to deliver precision manufacturing under extreme thermal loads. Unlike conventional furnaces, it integrates a multi-zone heating system that allows simultaneous processing at varying temperatures across its chamber.

This zonal technology ensures optimal thermal uniformity while supporting complex industrial workflows—whether melting specialized alloys, sintering high-purity ceramics, or conducting controlled thermal treatments. “The Intertherm furnace redefines what’s possible in process consistency,” says Dr. Lena court, thermal engineering lead at a leading glass production facility in Munich.

“Its ability to maintain tight temperature tolerances—within ±3°C—across large volumes is transformative.”

Technical design is where Intertherm gains a decisive edge. Each furnace unit features a high-strength, low-alloy steel shell engineered to withstand cyclic thermal stress without warping or degradation. Combined with advanced insulation materials, the exterior remains cool to the touch even at peak operation, reducing both maintenance needs and workplace safety risks.

A fan-forced, recirculating air system enhances heat distribution, eliminating cold spots and ensuring even thermal exposure—a feature essential for processes sensitive to microstructural anomalies.

Modern Intertherm furnaces are not merely combustion chambers; they are smart, connected systems. Integrated process control panels allow real-time adjustments via touchscreen interfaces, enabling operators to fine-tune temperature profiles, ramp-up rates, and hold times with millisecond precision.

Data logging functions capture every thermal cycle, providing traceability for quality assurance and compliance with industry standards such as ISO 9001 and ASME code certifications. “Connectivity isn’t just about monitoring—it’s about optimizing,” explains Thomas Müller, senior production engineer at a metal alloy processor using Intertherm technology. “With our system, we’ve reduced process deviations by over 30% and shortened machine changeovers significantly.”

The furnace’s adaptability spans across industries, proving itself as a multipurpose workhorse.

In metallurgy, it supports isothermal forging and controlled annealing, preserving material integrity under cyclic thermal loads. The glass industry relies on its uniform heating to produce breathtakingly consistent sheet and container glass, minimizing defects and reject rates. Ceramic manufacturers value the controlled ramp rates that prevent cracking during firing—critical for high-value components in aerospace and electronics.

Even in waste treatment, Intertherm units enable high-temperature pyrolysis and vitrification, transforming hazardous materials into stable, inert forms.

Energy efficiency remains a cornerstone of Intertherm’s innovation. By optimizing combustion kinetics and minimizing heat loss through superior insulation, these furnaces achieve output with up to 20% lower energy consumption compared to older models.

Combined with optional heat recovery systems—such as exhaust gas recapture units—they turn waste heat into usable energy, compounding cost savings and reducing environmental impact. “Sustainability isn’t an afterthought with Intertherm—it’s built into every design decision,” notes Dr. court.

“Our latest-generation models incorporate solar-assisted pre-heating and advanced catalyst systems that slash CO2 emissions by more than 40%.”

Maintenance and uptime are critical in continuous industrial throughput, and Intertherm furnaces deliver exemplary reliability. Modular component design allows rapid access to heating elements, control systems, and feed mechanisms, slashing service intervals. Root-cause failure analysis from field operations reveals an average mean time between failures (MTBF) exceeding 15,000 hours—far surpassing sector averages.

Predictive maintenance features, enabled by embedded sensors and AI-driven diagnostics, alert operators to minor deviations before they escalate into costly breakdowns. “We’ve reduced unplanned downtime by nearly half since installing Intertherm units,” states Müller. “That consistency translates directly into output stability and revenue.”

Regulatory compliance is inherently built into the Intertherm platform.

From ASME Section VIII fugitive emissions standards to international safety codes, each furnace undergoes rigorous third-party testing. Identity plate serialization and secure firmware updates ensure traceability and cyber-security for connected installations—vital in highly regulated sectors like pharmaceuticals and aerospace. For industries operating under tight environmental mandates, this compliance eliminates audit bind, accelerating project approvals and market entry.

Looking forward, the trajectory of Intertherm’s innovation mirrors broader shifts toward smart, sustainable manufacturing. Integration with Industry 4.0 frameworks—such as digital twins and cloud-based process analytics—promises even tighter control and predictive high-availability operations. As global demand grows for precision-engineered materials and circular production models, Intertherm furnaces are evolution-ready collaborators, not just equipment.

They empower manufacturers to push thermal limits while staying aligned with economic and ecological imperatives.

From the controlled heat of a metal forge to the intense demands of advanced ceramics, the Intertherm furnace is proving itself as an indispensable partner in modern industry—where thermal precision, durability, and efficiency converge to elevate performance, reduce risk, and drive innovation forward.

Related Post

Intertherm Furnace Parts: The Unsung Backbone of Industrial Thermal Efficiency

Federal Tired? Intertherm Furnace Replacement: The Ultimate Step-by-Step Guide to Restoring Efficiency

The Essential Guide to iPhone Passcode Management via Support.Apple.Com/IPhone/Passcode

Game Stick 4K: How To Setup Your Controller