Industrial Innovation: How Modern Industry is Redefining Global Productivity

Industrial Innovation: How Modern Industry is Redefining Global Productivity

In an era defined by digital transformation and sustainability imperatives, industrial innovation stands as the cornerstone of global economic advancement—redefining manufacturing efficiency, supply chain resilience, and technological integration at scale. Far beyond automation or robotics, today’s industrial revolution leverages interconnected systems, data-driven decision-making, and green manufacturing to transform how goods are produced and delivered worldwide. Industrialist leaders recognize that the future of industry lies not just in machines, but in intelligent, adaptive ecosystems built for agility and environmental responsibility.

At the heart of modern industrial transformation is the convergence of advanced technologies—Artificial Intelligence (AI), the Internet of Things (IoT), and cloud computing—forming what experts call Industry 4.0. This integration enables real-time monitoring, predictive maintenance, and dynamic optimization of production lines. As Dr.

Elena Marquez, Chief Technology Officer at a leading industrial tech firm, explains: “We’re no longer just automating processes—we’re creating networks where machines learn, adapt, and improve independently. This shift drives unprecedented efficiency and reduces waste across the operational spectrum.”

Data analytics now serve as the nervous system of industrial operations. Sensors embedded in machinery generate streams of operational data, which AI algorithms analyze to forecast maintenance needs—preventing costly downtime and extending equipment life.

For instance, predictive analytics in automotive manufacturing have reduced unplanned downtime by up to 45%, according to recent industry reports. Smart factories leverage this insight to operate at near-zero disruption, optimizing throughput without sacrificing quality.

Moreover, IoT connectivity binds every stage of production—from raw material sourcing to final assembly—into a unified digital thread. This end-to-end traceability enables rapid response to supply chain challenges, quality deviations, or regulatory shifts.

Automotive giants like Ford and Siemens have implemented IoT-enabled supply chains that detect delays or bottlenecks within seconds, allowing immediate course correction. “The real-time visibility these systems offer transforms reactive management into proactive strategy,” notes Thomas Reinhardt, Industrial Digitalization Lead at a major engineering conglomerate.

Sustainability is no longer a peripheral concern but a core industrial imperative.

The pressure to decarbonize manufacturing has spurred investments in green technologies: electrified production lines, renewable-powered facilities, and circular economy models that minimize waste and recycle materials. The European Union’s Green Deal Industrial Plan, for example, allocates over €200 billion to modernize industrial baselands with low-carbon technologies—supporting a shift toward net-zero emissions by 2050. In heavy industries such as cement and steel, carbon capture, utilization, and storage (CCUS) systems are being piloted at scale, proving that decarbonization and productivity can coexist.

Industrial innovation also reshapes labor dynamics.

Rather than displacing workers, advanced industrial systems augment human capabilities through augmented reality (AR) interfaces, collaborative robotics (cobots), and upskilling programs. Germany’s “Industrie 4.0” initiatives emphasize workforce transformation, where employees transition from manual tasks to supervisory, analytical, and maintenance roles—ensuring that human expertise remains central in smart factories.

Supply chain resilience, long tested by global disruptions, is being rebuilt via digital twins and decentralized manufacturing networks. Digital twin technology—virtual replicas of physical systems—allows engineers to simulate production scenarios, optimize logistics, and stress-test operations before implementation.

Companies like Boeing and Unilever now use digital twins to model everything from factory layouts to inventory flows, enhancing responsiveness and reducing risk.

In emerging economies, industrial innovation drives inclusive growth. Nations such as India and Vietnam are leapfrogging legacy infrastructure with modern industrial parks equipped for smart manufacturing, attracting foreign investment and skilled talent. These hubs showcase how integrated technology and policy can elevate regional economies while meeting global competitiveness standards.

Industrialist pioneers emphasize that innovation is not confined to large corporations. Small and medium enterprises (SMEs) increasingly access cloud-based industrial platforms, AI-driven quality control, and modular automation—leveling the playing field and fostering a globally distributed industrial ecosystem. Open-source software and plug-and-play IoT devices have democratized advanced manufacturing tools, enabling faster adoption and experimentation across sectors from aerospace to consumer goods.

Looking ahead, the trajectory of industrial innovation point toward even deeper integration of AI, edge computing, and sustainable materials.

Quantum computing simulations may soon revolutionize materials science, while AI-driven design generative systems promise faster, more efficient product development. Yet, amid rapid advancement, ethical considerations—data privacy, workforce equity, and environmental stewardship—remain central. Industrialists agree: true progress balances technological leapfrogging with social and ecological responsibility.

The industrial landscape today is not simply evolving—it is reinventing itself. From AI-optimized factories to carbon-neutral supply chains and human-centered automation, industrial innovation is forging a future where efficiency, sustainability, and resilience converge. As global demands intensify, the industry’s ability to harness and align these forces will define not only economic success but the very pace of global progress.

The industrial renaissance is underway, and the world is watching closely—because the next era of manufacturing isn’t just bigger, faster, or cheaper. It’s smarter.

Related Post

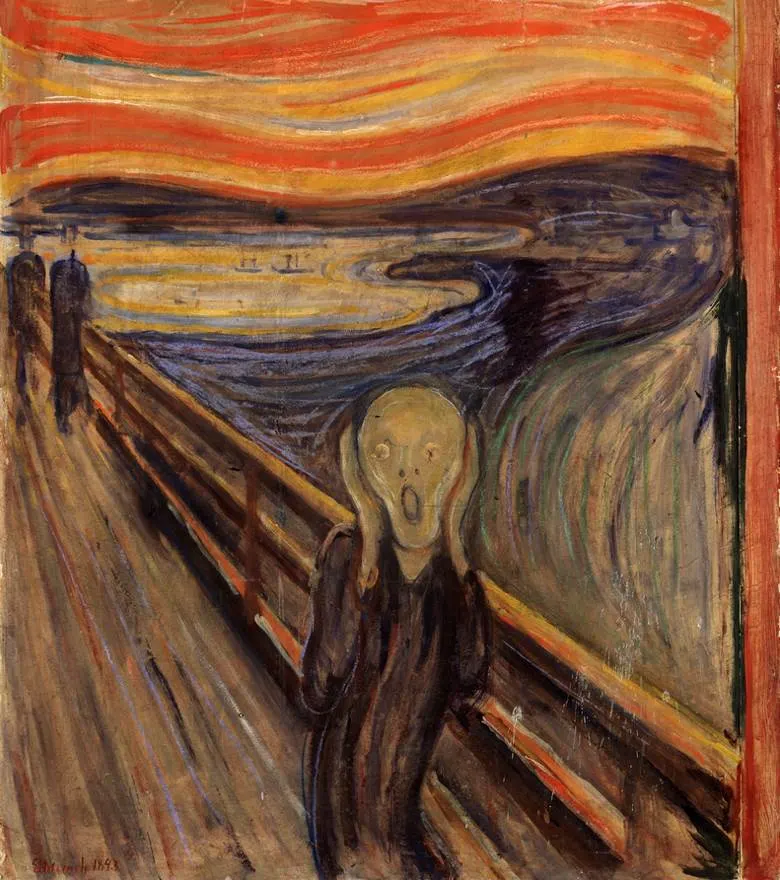

Behind the Brushes of Fear: Famous Scary Paintings That Haunted History

Unmasking Aperiphobia: The Silent Fear That Drives People from Fresh Air

Canvas at Florida Technical College: Mastering Digital Learning Since 1914