How Vinegar’s Purity Unlocked: A Precise Quantitative Titration Analysis

How Vinegar’s Purity Unlocked: A Precise Quantitative Titration Analysis

Vinegar, a household staple for millennia, remains far more than a simple condiment—its acetic acid content, often Maltriacetic Acid or Glacial Acetic Acid depending on production, dictates its culinary, industrial, and scientific value. But what separates a kitchen grade vinegar from pharmaceutical-grade? The answer lies in precision: quantitative acid-base titration, a laboratory standard that reveals vinegar’s exact acetic acid concentration, revealing a hidden layer of quality assurance often overlooked by consumers.

By measuring alkaline requirements to neutralize carboxylic acid components, this method delivers definitive data that shapes production standards, regulatory compliance, and even health impact assessments.

At its core, a quantitative titration of vinegar quantifies acetic acid through a direct acid-base reaction, typically using standardized sodium hydroxide (NaOH). The approach hinges on stoichiometric equivalence: each mole of acetic acid reacts with one mole of NaOH, enabling accurate mass-to-mole conversion. “This is not guesswork,” explains Dr.

Elena Marquez, analytical chemist at the Institute for Food Chemistry. “Titration transforms vinegar into a measurable system, uncovering its true acid strength with scientific rigor.” Using phenolphthalein as a color indicator, the endpoint—when solution shifts from pink to colorless—marks the precise neutralization point, allowing millimolar precision.

The methodology follows a structured, reproducible protocol. A standard 0.1 M NaOH standard solution is added incrementally to vinegar samples using a mucic acid indicator or automated burette, ensuring accuracy.

Common metrics include:

- Initial acidity sample: Determines base concentration required for neutralization, typically reported in g/L acetic acid.

- Equivalence point: The volume of NaOH required to neutralize all acid—this directly correlates to acid concentration via the equation:

Macid × Vacid = Mbase × Vbase - pH at endpoint: Measured semi-automatically, reflecting solution stability and confirming reaction completion.

Results reveal critical insights: industrial white vinegars often contain 5–8% acetic acid by weight, translating to ~4.8–7.9 g/L based on titration readings. In contrast, fruit-based or "baking" vinegars may range from 4–6%, while specialized acidic products—such as glacial acetic acid used in laboratories—achieve concentrations above 90%. These values are not arbitrary; they determine market classification, shelf-life predictions, and safety protocols.

The US Pharmacopeia, for example, mandates titration-based verification for vinegar used in medicinal preparations.

Historically, vinegar analysis relied on gravimetric methods—precipitating bases and weighing residues—a slow, labor-intensive process unsuitable for routine quality control. Titration, standardized in the early 20th century, revolutionized the field by offering rapid, cost-effective, and highly repeatable data. “Titration is the linchpin of vinegar authenticity,” notes chemist Robert Finch from a leading agrochemical lab.

“It doesn’t just quantify acid—it validates shelf integrity and consumer trust.”

The impacts of this quantitative insight extend beyond industry. For food safety, precise titration ensures potency meets label claims, preventing misleading marketing. In healthcare, acetic acid’s therapeutic dosage depends on accuracy; improper amounts could impair safety, especially in clinical applications.

Moreover, academic research on vinegar’s antimicrobial or digestion benefits hinges on knowing exact acetic acid levels—no lower precision allows reliable conclusions. As Dr. Marquez emphasizes, "Titration bridges tradition and science, preserving vinegar’s legacy while grounding it in measurable truth."

Modern titration integrates automation and advanced indicators, including pH-stat systems and spectrophotometric endpoints, enhancing sensitivity down to individual millimoles per liter.

These refinements are pivotal for high-value applications: pharmaceutical-grade vinegar used in biopharmaceutical formulations demands near-perfect purity, measurable only through rigorous titration protocols. Even craft producers now adopt titration to certify premium products, distinguishing artisanal quality amid mass-market uniformity. Each result, whether confirming 6.2% acetic acid or detecting contamination, reinforces transparency across supply chains.

What emerges from this quantitative scrutiny is a clearer, data-driven portrait of vinegar.

Far from a uniform solution, its acidity varies by formulation, origin, and intent—revealed only through meticulous titration. This method not only defines vinegar’s scientific identity but empowers regulation, innovation, and consumer confidence. In the quiet hum of titration burettes, the story of vinegar—acetic acid, tradition, and precision—comes into sharp focus.

Quantitative analysis of vinegar via titration is not merely a lab technique; it is a cornerstone of quality, safety, and authenticity in one of the world’s oldest liquids.

With each precise measurement, vinegar’s silent strength is quantified, proving that even the most familiar substances benefit from the exacting lens of science.

.PNG)

Related Post

römàn 1–20: Decoding the 20 Core Pillars Shaping Modern Innovation

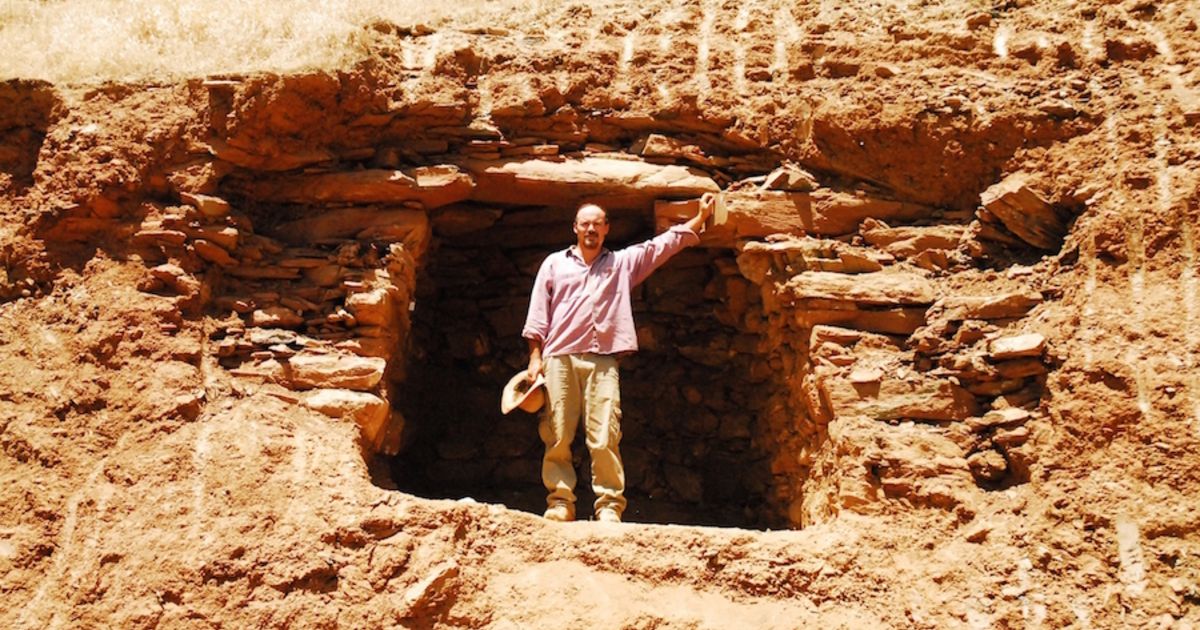

Галатасарай: The Underwater Archaeology Gem Here, Syria’s Hidden Heritage Beneaths the Waters

Korean Martial Arts: Unveiling the Dynamic Heartbeat of South Korea’s Fighting Styles

Dr Umar Book: A Pioneering Voice in Behavioral Health and Holistic Wellness