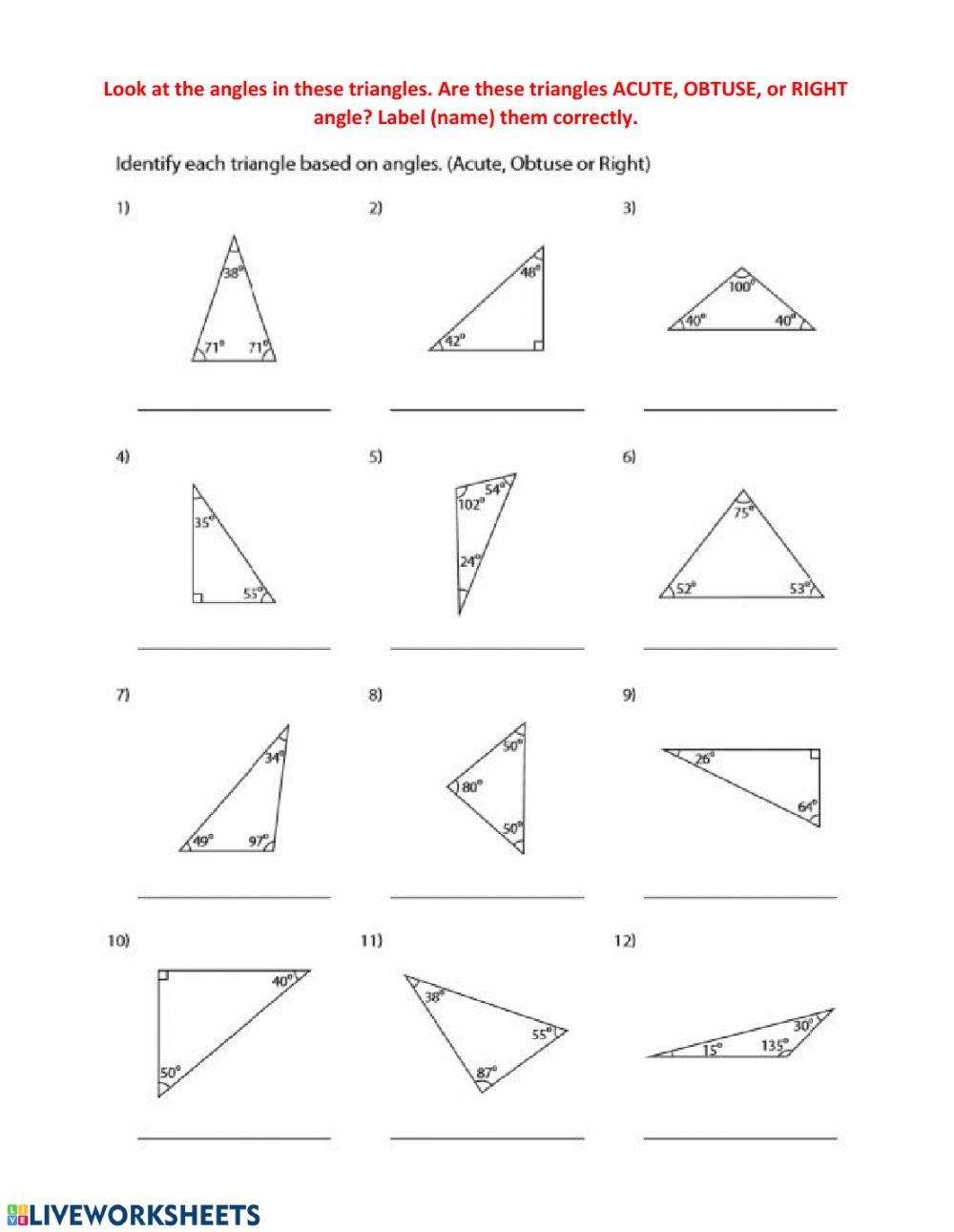

Eggy Cart: Revolutionizing Egg Packaging with Smart Design and Sustainable Innovation

Eggy Cart: Revolutionizing Egg Packaging with Smart Design and Sustainable Innovation

In a world increasingly focused on sustainability and efficiency, Eggy Cart emerges as a trailblazer in egg packaging, combining intelligent engineering with eco-conscious materials to redefine how eggs reach consumers. This innovative solution doesn't just protect fragile eggs—it transforms the economics and environmental footprint of packaging in the fresh food supply chain.

Eggy Cart is not a single product but a suite of advanced egg containers engineered from recycled, plant-based biopolymers and modular design principles.

Unlike traditional cardboard or styrofoam cartons, it incorporates a patented—a revolutionary lightweight lattice structure that enhances shock absorption while reducing material use by up to 40%. This engineering leap translates to lower transportation emissions, faster stacking, and reduced breakage during logistics.

The packaging’s design rests on three core principles: protection, sustainability, and scalability. Traditional egg cartons often fail under pressure or degrade prematurely in humid conditions—Eggy Cart overcomes these weaknesses.

"Our lattice serves as both a cushion and a carrier, distributing impact evenly across the entire structure," explains Dr. Lena Patel, Product Engineer at Eggy Cart. "Tests show it prevents cracks at drops as high as 1.8 meters—twice the impact standard for conventional packages."

Sustainability lies at the heart of Eggy Cart’s innovation.

Each packaging unit is made from 85% recycled content, including post-consumer materials and sustainably sourced cellulose fibers. The biopolymer outer shell dissolves harmlessly in industrial composting facilities within 12 weeks, leaving no microplastic residue. When compared to conventional polystyrene alternatives, Eggy Cart reduces carbon emissions by approximately 60% over its lifecycle—a critical advantage in a sector historically dependent on fossil fuel–based plastics.

The modular design ensures seamless integration across diverse production lines.

From automated egg sorting to retail shelf placement, Eggy Cart systems adapt effortlessly. Each carton holds precisely 12 eggs, arranged in a staggered alignment that maximizes space on pallets and minimizes movement during transit. This precision cuts packing time by 15% in commercial settings, directly improving throughput for bakeries, supermarkets, and dairy distributors.

Beyond physical durability, Eggy Cart integrates smart tracking technology.

Embedded NFC chips allow for real-time monitoring of temperature, humidity, and shock exposure throughout the supply chain. Retailers and producers receive instant alerts if conditions deviate from safe thresholds, enabling proactive quality control and reducing waste. "This level of control isn’t just about eggs—it’s about trust," says Mars Hilton, CEO of Eggy Cart.

"We give every batch a digital story, so you know exactly where and how the eggs were protected."

Adoption of Eggy Cart reflects a broader shift in consumer and industry expectations. As global demand for ethically sourced and low-impact products rises, packaging innovation becomes non-negotiable. Retail chains in Europe and North America have begun replacing legacy egg cartons with Eggy Cart models, driven by both regulatory pressures and growing customer preference for sustainable practices.

The packaging’s transparent manufacturing data also supports corporate ESG reporting, helping businesses showcase measurable environmental progress.

Use cases for Eggy Cart span from high-end farm-to-table bakeries to urban grocery chains. In pilot programs, participating stores reported:

- 20% lower breakage rates during delivery

- Zero box complaints related to crushing or moisture damage

- 15% improvement in inventory turnover due to faster handling

Despite its advanced capabilities, Eggy Cart addresses cost concerns through long-term value. The initial investment is offset by reduced packaging waste, lower replacement rates, and energy savings in refrigerated transport—all contributing to a faster return on investment within 18 months.

Early market analysis confirms that brands using Eggy Cart experience “a seamless balance between premium presentation and responsible sourcing,” according to supply chain analysts at GreenPack Solutions.

Looking ahead, Eggy Cart is evolving beyond egg packaging. The modular lattice concept inspires new applications in produce and dairy—where impact resistance and environmental impact are equally critical. Development teams are testing hybrid materials that open doors to compostable delivery for avocados and bulk dairy shipments, potentially transforming how perishables travel from farm to store.

Eggy Cart exemplifies how thoughtful design can resolve deep-seated challenges in food logistics.

It delivers robust protection without sacrificing environmental integrity, scales across industries without compromising performance, and fosters transparency in an industry often obscured by opaque packaging. As food systems worldwide strive for resilience and responsibility, Eggy Cart isn’t just a packaging solution—it’s a blueprint for innovation where sustainability and practicality go hand in hand.

Related Post

Unlocking Math Mastery: How Eggy Cart & Hooda Math Revolutionize Learning

Iceberg Slim .Txt: The Secret Behind Text Markers That Define Digital Discretion

Kat Timpf Pregnant Due Date Everything You Need to Know When Is It — The Timpf Way

Understanding the Definition of Definition: The Simple Guide That Unlocks Clarity in Language