Ductile Iron Pipes in Saudi Arabia: The Backbone of the Kingdom’s Water Infrastructure

Ductile Iron Pipes in Saudi Arabia: The Backbone of the Kingdom’s Water Infrastructure

Saudi Arabia’s ambitious infrastructure development, driven by Vision 2030, has intensified the demand for durable, high-performance materials—among which ductile iron pipes stand out as a transformative solution. These specialized cast iron materials, engineered for superior strength and resilience, have become the gold standard for underground water and wastewater conveyance across the arid landscape. From Riyadh’s expanding metropolitan networks to remote agricultural projects, ductile iron pipes offer a reliable, long-lasting alternative to traditional materials, ensuring water security in one of the world’s most challenging environments.

Designed to withstand extreme pressures, aggressive soil conditions, and the corrosive nature of conventional piping systems, ductile iron pipes deliver unmatched performance in Saudi Arabia’s variable climate—extreme heat during summer and seasonal flooding in certain regions. Unlike brittle cast iron or PVC, their unique nodular graphite structure provides ductility that absorbs stress, reducing the risk of sudden failures. “Ductile iron represents a significant leap forward in pipeline integrity,” notes Dr.

Fahd Al-Mutairi, a senior civil engineer overseeing public infrastructure in the Ministry of Municipal and Rural Affairs. “Its ability to endure years of pressure without deformation makes it ideal for the Gulf’s dynamic hydrological demands.”

Available in a spectrum of diameters—from 100 mm to over 1,200 mm—and standard lengths ranging from 4 to 12 meters, ductile iron pipes are engineered for modular installation and easy replacement. The casting process enables precise dimensional accuracy, ensuring seamless connections with minimal leakage.

Each pipe section is subjected to rigorous quality control, including hydrostatic testing and non-destructive evaluation, confirming compliance with international standards such as EN 1462 (for ductile iron) and Gulf-specific codes enforced by Saudi standards bodies. “Installation speed and durability mean less disruption and lower lifecycle costs,” says engineer Layla Hassan of Saudi Water Industries. “We’re not just building pipes—we’re investing in long-term resilience.”

The adoption of ductile iron aligns with Saudi Arabia’s strategic push toward sustainable infrastructure.

With a focus on reducing water loss—currently estimated at around 20% nationwide—permanent, leak-resistant piping is critical. Projects across the kingdom, including the massive Riyadh Metro water supply and the Eastern Province’s agricultural irrigation upgrades, increasingly favor ductile iron for its proven longevity—often rated at 75 to 100 years, compared to 40–60 years for many PVC systems. Environmental benefits also emerge: reduced maintenance translates to lower emissions from repair vehicles, and the recyclability of ductile iron supports circular economy goals.

Installation in Saudi Arabia benefits from a maturing supply chain and skilled local contractors trained in modern trenchless and vertical shaft methods. Pre-cast ductile sections are transported efficiently to job sites, accelerating project timelines. In remote regions, where logistics pose challenges, the pipes’ robustness under extreme ground movement—caused by sand shifts or minor seismic activity—proves invaluable.

“Civil contractors report reduced downtime and fewer emergency interventions,” says project manager Khalid Abdulaziz of Aramco Infrastructure Services. “Ductile iron pipes deliver consistent performance even in the harshest conditions.”

Compliance with national standards ensures that every ductile iron pipe installed in Saudi Arabia meets stringent safety and environmental criteria. The Saudi Standards, Metrology and Quality Organization (SASO) mandates adherence to EN 1462, with local modifications addressing corrosion risks from high groundwater salinity.

Additionally, the Vision 2030 framework incentivizes the use of advanced materials through procurement policies favoring long-term value and sustainability. This regulatory push has accelerated adoption by municipal utilities, private developers, and agricultural contractors alike.

Looking ahead, the role of ductile iron pipes in Saudi Arabia’s development is poised to expand further.

Innovations in smart pipeline integration—such as embedded sensors for real-time flow and pressure monitoring—are being tested in pilot projects, promising enhanced asset management. As water resources become increasingly critical amid climate pressures, the nation’s investment in high-performance piping material exemplifies a strategic, forward-looking approach to infrastructure resilience. Ductile iron pipes are not just engineering components—they are foundational enablers of sustainable growth, security, and public safety in today’s rapidly evolving landscape.

In essence, ductile iron pipes represent a paradigm shift in how Saudi Arabia manages its essential water systems. Engineered for strength, reliability, and environmental fitness, they bridge the gap between engineering excellence and real-world performance. With continued innovation and implementation, these pipes are safeguarding the kingdom’s water future—one durable link at a time.

Related Post

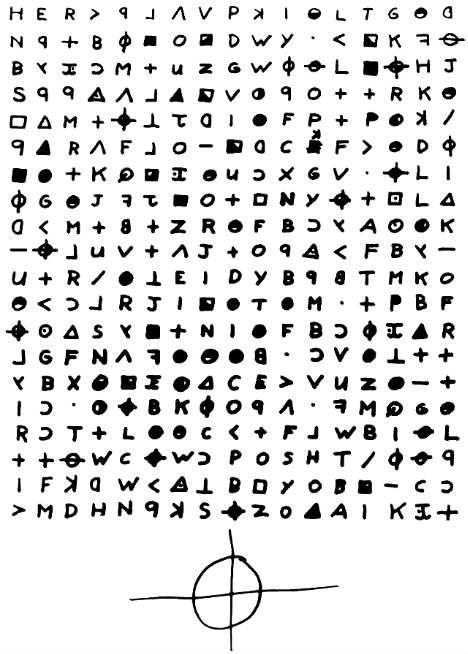

Zodiac Killer’s Ciphers Finally Cracked: Decoding Decades of Cryptic Terror

Iisapolino Cocomelon Everything You Need to Know: The Global Sensory Sensation Behind the Beloved Show

Steven Universe Revealed: The Unbreakable Power and Legacy of Sugilite

Task Manager: The Unsung Power Behind Human Productivity