45 Millimeters to Inches: The Precise Conversion That Opens Doors in Engineering, Design, and Everyday Life

45 Millimeters to Inches: The Precise Conversion That Opens Doors in Engineering, Design, and Everyday Life

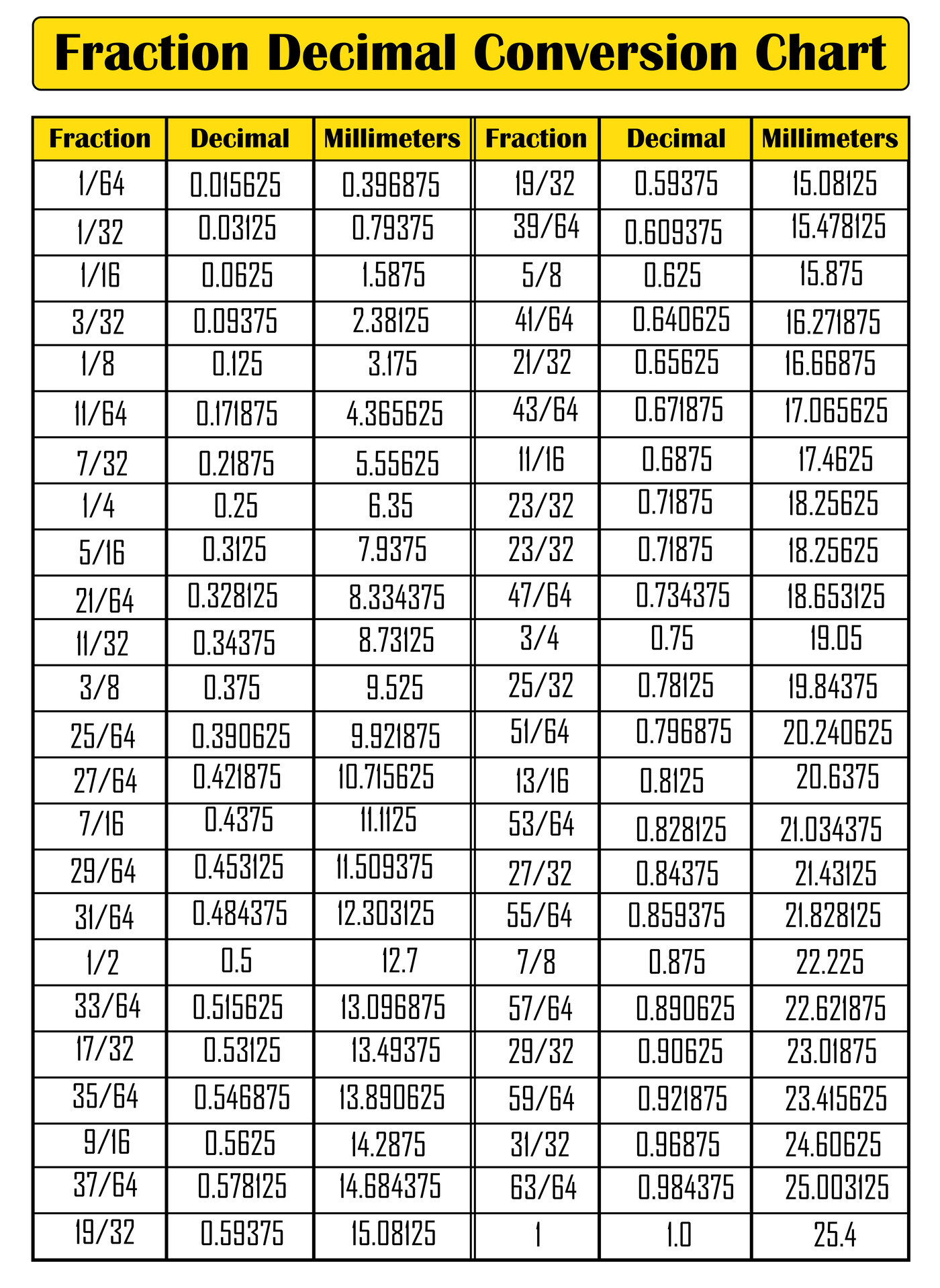

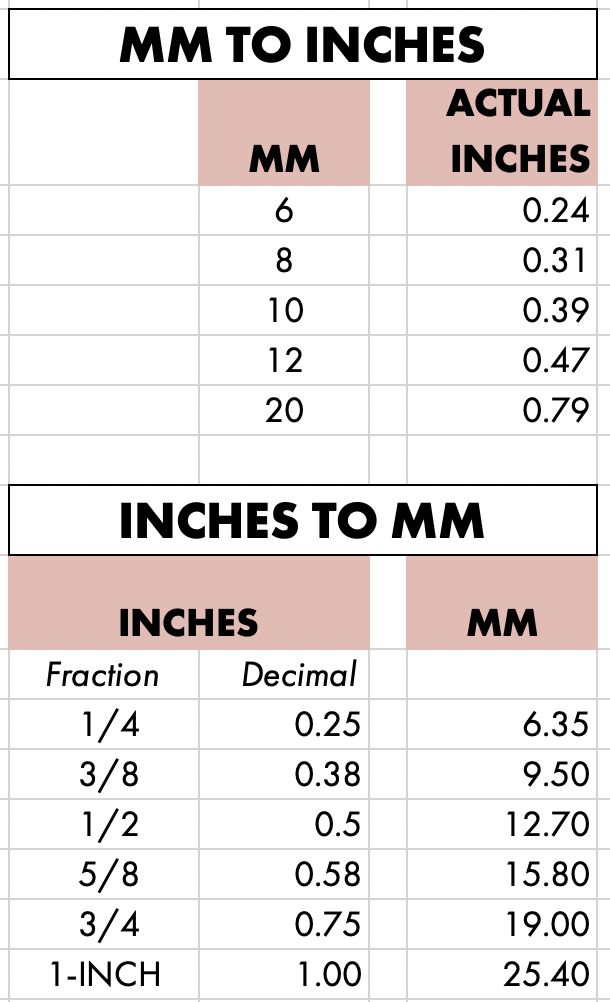

When technical professionals need to translate measurements with accuracy, the conversion of millimeters to inches emerges as a fundamental bridge between metric and imperial systems. At a exact ratio of exactly 25.4 millimeters per inch—where 1 inch equals 25.4 mm—this decimal precision enables seamless communication across industries. Whether in manufacturing tolerances, architectural blueprints, or international product specifications, understanding how 45 mm translates to inches reveals not just a number, but a gateway to reliable design and compatibility.

To clarify the conversion: dividing 45 by 25.4 yields exactly 1.77352906 inches. Rounded to a practical two decimals, 45 mm equals 1.77 inches—a value that balances precision with usability. This number may seem simple, but in fields where millimeters matter, such as aerospace components, watchmaking, or electronics assembly, even fractional shifts affect performance and fit.

For engineers and designers, millimeter-to-inch conversions are not abstract math—they are critical checkpoints. Consider a precision-machined bracket where loose fitments due to rounding can compromise structural integrity. If a part requires a length of 45 mm, specifying 1.77 inches ensures compatibility with U.S.

inventory systems that rely on imperial units, preventing costly rework. “Accuracy starts with understanding the conversion,” states Maria Chen, senior metrology engineer at Precision Dynamics Inc. “A 0.02-inch deviation in a 45 mm component might be acceptable in some contexts, but in high-tolerance applications, it’s non-negotiable.” The metric system’s decimal foundation simplifies the math: since every millimeter is exactly 1/25.4 of an inch, converting 45 mm becomes a systematic division.

This consistency across scales reduces human error—errors that can cascade through production lines and supply chains. In manufacturing, specification sheets often list dimensions in modules that transition smoothly between systems, making 45 mm → 1.77 inches a routine yet vital exchange. Historically, the imperial system dominated much of the globe, particularly in construction and automotive industries, but globalization has driven demand for metric fluency.

Today, international standards like ISO 31000 and ASTM specifications expect seamless interoperability, requiring precise cross-unit translation. A 45 mm panel cut for a Japanese robot system installed in a U.S. factory must conform to imperial measurements to fit correct安装 spaces and fastening systems.

Benefits of precise millimeter-to-inch conversion extend beyond industrial applications. In consumer products, from smartwatch casings to precision instruments, designers use millimeters for exact contouring while ensuring compatibility with global markets using inches. For example, the internal cavity of a smartphone battery module rated at 45 mm outer length fits seamlessly in devices designed for a 1.77-inch profile—aligning production efficiency with end-user expectations.

Technical Foundations: The Decimal Root of Every Conversion The relationship between millimeters and inches is rooted in a precise decimal fraction: 1 inch = 25.4 mm.This conversion factor emerged from the 1795 French Académie des Sciences standardization that defined the inch as exactly 25.4 millimeters. Unlike approximations that dilute precision, this fixed ratio eliminates uncertainty. For example:

- 45 mm = 45 ÷ 25.4 = 1.77352906 inches, commonly rounded to 1.77 in practical use.

- 10 mm = approximately 0.3937 inches, close to 0.4 inches but measured precisely in industrial contexts.

- 100 mm = 3.937 inches — a value engineers trust when aligning parts across borders.

Yet, understanding the underlying math remains critical. “Software tools handle the math, but human expertise ensures correct interpretation,” warns engineer Javier Ruiz. “A wrong conversion can mean defective parts, safety risks, or financial loss.” In sectors like aerospace, where components endure extreme conditions, millimeter accuracy translates directly to safety.

The fuselage of a military aircraft may integrate numerous 45 mm-thick panels, each part of a system demanding exact spacing and alignment. “A 0.014-inch mismatch could cause stress fractures,” says Dr. Elena Petrova, a materials scientist specializing in UAV construction.

“So knowing 45 mm equals 1.77 inches isn’t just academic—it’s safety-critical.” Even in everyday life, the conversion matters. Consider 3D-printed parts ordered online: a model designed in millimeters must translate accurately to inches for proper mounting on imperial-sized mounts or displays. Manufacturers publish dimensional ranges in both systems, often specifying 45 mm or its 1.77-inch equivalent to ensure end users avoid fitment errors.

Applications Across Industries Require Unwavering Precision Across manufacturing, woodworking, medical device production, and automotive assembly, 1.77 inches derived from 45 mm ensures global compatibility. Automotive engineers designing engine components in metric units must align with U.S. standards using imperial conversions—relying on the 25.4 mm benchmark for fit, function, and safety.

“Our global supply chain depends on consistent measurements,” explains Derek Lynn, production director at EuroMotion Ltd. “A 45 mm bracket that converts cleanly to 1.77 inches connects seamlessly from plants in Germany to warehouses in Ohio.” Woodworkers and cabinetmakers also depend on this relationship. A custom furniture piece requiring 45 mm joinery depth must translate precisely to 1.77 inches for true alignment with imperial-cut tabletop thicknesses.

“In detailing every groove or mortise,” says master woodworker Thomas Europe, “using accurate conversions avoids costly rework and ensures artistry meets practicality.” Technology sectors integrate these units too. Semiconductor packaging often lists chip dimensions in millimeters—mapping precisely to the internal case thickness measured in inches. A 45 mm chip fits reliably in a 1.77-inch probe station, illustrating how microscopic precision interfaces with broader system design.

The universality of 25.4 mm per inch underpins economic efficiency. By adopting this standard, international trade avoids translation delays and manufacturing bottlenecks. ISO 31000, a globally recognized standard for measurement consistency, mandates such precision.

“Harmonization of units reduces friction,” observe trade analysts at the World Trade Organization. “Exact conversions like 45 mm to 1.77 inches make cross-border commerce cleaner, faster, and less error-prone.”

Beyond technical utility, the 45 mm to 1.77 inch conversion reflects a deeper principle: in a globalized world, precision in units is precision in trust. Dimensional accuracy safeguards product performance, enhances user experience, and prevents costly failures—whether in a watch’s gear alignment or a satellite antenna’s deployment mechanism.

Technological tools now embed these conversions into CAD software, mobile apps, and industrial sensors, yet the underlying math remains essential.Engineers must still verify, validate, and understand the context—especially when tolerances near critical edges. As Dr. Chen observes, “Technology amplifies our reach, but human judgment ensures reliability.” The exactness of 45 mm → 1.77 inches is more than a statistic; it’s a benchmark of quality, consistency, and global connectivity.

In construction, product design, and advanced manufacturing, millimeter-to-inch conversions define clarity. 45 mm → 1.77 inches is not just a number—it’s a standard that enables seamless integration, reduces risk, and builds bridges between systems. As industries evolve, mastery of such conversions remains a cornerstone of precision engineering and international collaboration, ensuring that every component, no matter how small, fits perfectly in the larger design.

![Millimeters to Inches Converter: Instant & Precise Conversion [2026]](https://calcufacil.com/wp-content/uploads/2025/09/cropped-Generated-Image-September-05-2025-9_27PM-1-300x100.jpeg)

Related Post

Unveiling John Summit’s Net Worth: How a Visionary Built a $1.2 Billion Empire

Elon Musk’s Net Worth in Rupees: How the Billionaire’s Fortune Translates to India’s Economy

Unlock the Power of Lessgames: Transforming Digital Learning Through Engaging, Gamified Experience

Tyus Jones Wife: The Private Life Behind the WNBA Star’s On-Court Excellence